TSIP R&D division develops and proposes cutting-edge technology solutions in AI/ML.

We overview our “Data Analytics” and “Computer Vision” research activities.

Data Analytics

Optimization solution: Boiler Combustion Optimization (BCO)

- We can improve the power plant efficiency by optimizing operational timing for boiler combustion & cleaning, which is calculated based on the machine learning method. The service architecture is simple & scalable and can be applied to an existing power plant system.

- Boiler Combustion Optimization(BCO) solution for power plant system was registered on Toshiba SPINEX Marketplace.

Toshiba SPINEX Marketplace: Boiler Operation Optimization

https://www.spinex-marketplace.toshiba/en/services/boiler-operation

*This project is a collaboration work with Toshiba Energy Systems & Solutions Corporation and sponsored by New Energy and Industrial Technology Development Organization, Japan

Edge AI technology

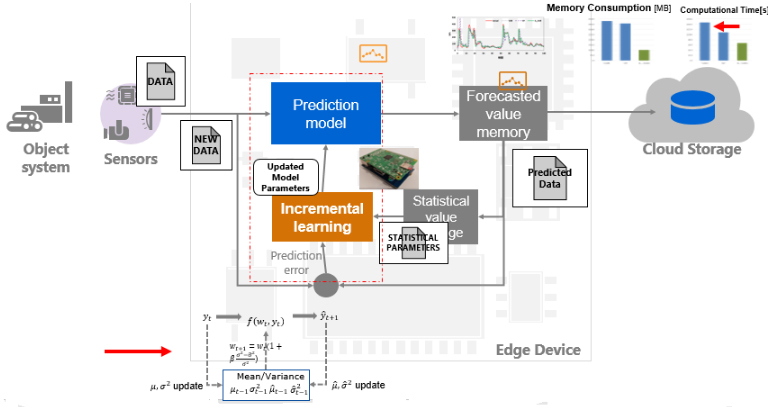

- IoT systems are the source of generating a huge amount of time series data. Deep neural networks and advanced machine learning algorithms provide precise forecasting using generated time series data. But, it requires computationally expensive infrastructure like cloud computing and GPU machines. Cloud computing is not feasible in the time-critical decision-making process in the factory. The decision must be made for newly generated input data.

- Edge computing is the solution for faster responses. However, edge devices have limited memory and processing power capabilities. Incremental learning is the solution used in Edge devices for a speedy response without compromising the prediction accuracies. We proposed ILVAR (Incremental Learning Vector Auto Regression for Forecasting with Edge Devices) for time sequential signal forecasting and published it in IEEE ICMLA.

Pesala, V., Paul, T.K., Ueno, K., Bugata, H.G., & Kesarwani, A. (2021). Incremental Learning Vector Auto Regression for Forecasting with Edge Devices. 2021 20th IEEE International Conference on Machine Learning and Applications (ICMLA), 1153-1159.

Figure: Incremental Learning at the Edge

Residual Signature Analysis for Wind Turbine Failure Prognosis

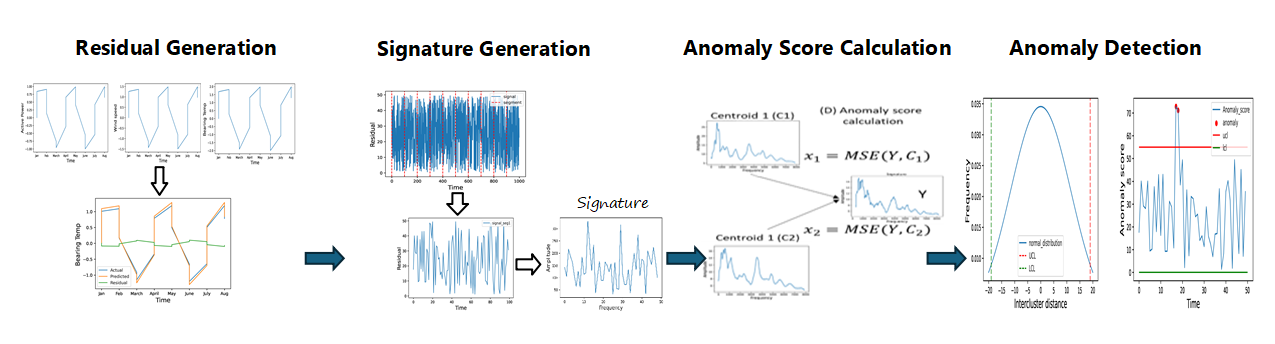

To improve the operation and maintenance of wind turbines, our approach revolutionizes failure prognosis beyond conventional methods. The proposed method advances the capabilities of existing residual analyses inspired by electrical signature analysis used in motor failure detection.

- Residual Generation - Residual generation is crucial for accurate performance analysis in systems exposed to environmental factors, as it eliminates the effects of external variables, such as seasonal changes, on the data being examined. This ensures that evaluations are based on the intrinsic behavior of the system rather than external influences.

- Signature Generation - This step enhances the detection of failure signs with a precise temporal resolution, allowing for more accurate monitoring. This process effectively manages the fluctuation of residual errors, reducing noise and improving the reliability of failure detection.

- Anomaly Score Calculation - The anomaly score is calculated as the mean squared error (MSE) distance from a segment’s signature to the nearest centroid, accounting for variations due to aging or different operational conditions.

- Anomaly Detection - To identify anomalies, control charts are used to signal when a process strays from its normal state. These charts may feature variable or fixed limits, including an Upper Control Limit (UCL) and a Lower Control Limit (LCL), which are determined based on the anomaly scores from the training data.

This innovative approach offers a scalable and efficient solution to extend the lifespan and improve the safety of wind energy operations.

Publication: T. Paul, V. Reddy, S. P. K. Ayyagari and K. Nishino, "Residual Signature Analysis for Wind Turbine Failure Prognosis," 2023 IEEE PES Innovative Smart Grid Technologies Europe (ISGT EUROPE), Grenoble, France, 2023, pp. 1-5, doi: 10.1109/ISGTEUROPE56780.2023.10407545.

Computer Vision

We will assist the industry in achieving its tasks utilizing machine learning method for images and videos. The industry problems range from classification, segmentation, analysis, quality measurements, anomaly detection, and image generation. In most cases, more data or the lack of data for training is challenging. We are trying to harness existing methods and developing novel methods to achieve the goal.

AI steel grading

- Human professional comparable steel quality grading service was registered to Toshiba SPINEX Marketplace (METALSPECTOR/AI).

- We can estimate steel grades from micrographs of the steel surface. We improve the estimation accuracy utilizing multiple deep learning methods and increasing the number of image data for dictionary learning.

TOSHIBA SPINEX Marketplace: METALSPECTORtm/AI

https://www.spinex-marketplace.toshiba/ja/services/metalspector-ai

TOSHIBA SATLYS Solutions: METALSPECTORtm/AI

* This project is a collaboration work with Toshiba Digital Solutions Corporation

Domain Adaptation

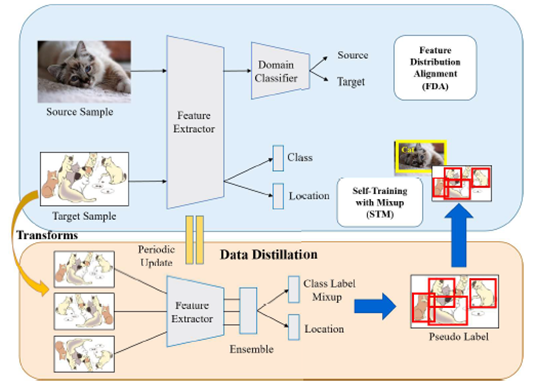

- Most real-time applications have fewer data (target data) to train deep learning-based methods. Directly utilizing existing methods trained on other kinds of data (source data) does not yield satisfactory results due to a significant domain gap between target and source data.

- We propose unsupervised domain adaptation techniques to mitigate issues like domain gaps. This method uses label-rich source domain information to generate labels for the target domain and then refine it to generate more accurate labels for the target domain.

Maurya, J., Ranipa, K. R., Yamaguchi, O., Shibata, T., & Kobayashi, D. (2023). Domain Adaptation Using Self-Training With Mixup for One-Stage Object Detection. In Proceedings of the IEEE/CVF Winter Conference on Applications of Computer Vision (pp. 4189-4198).

Figure: Method to utilize label-rich source domain data knowledge to generate labels to non-labelled target domain